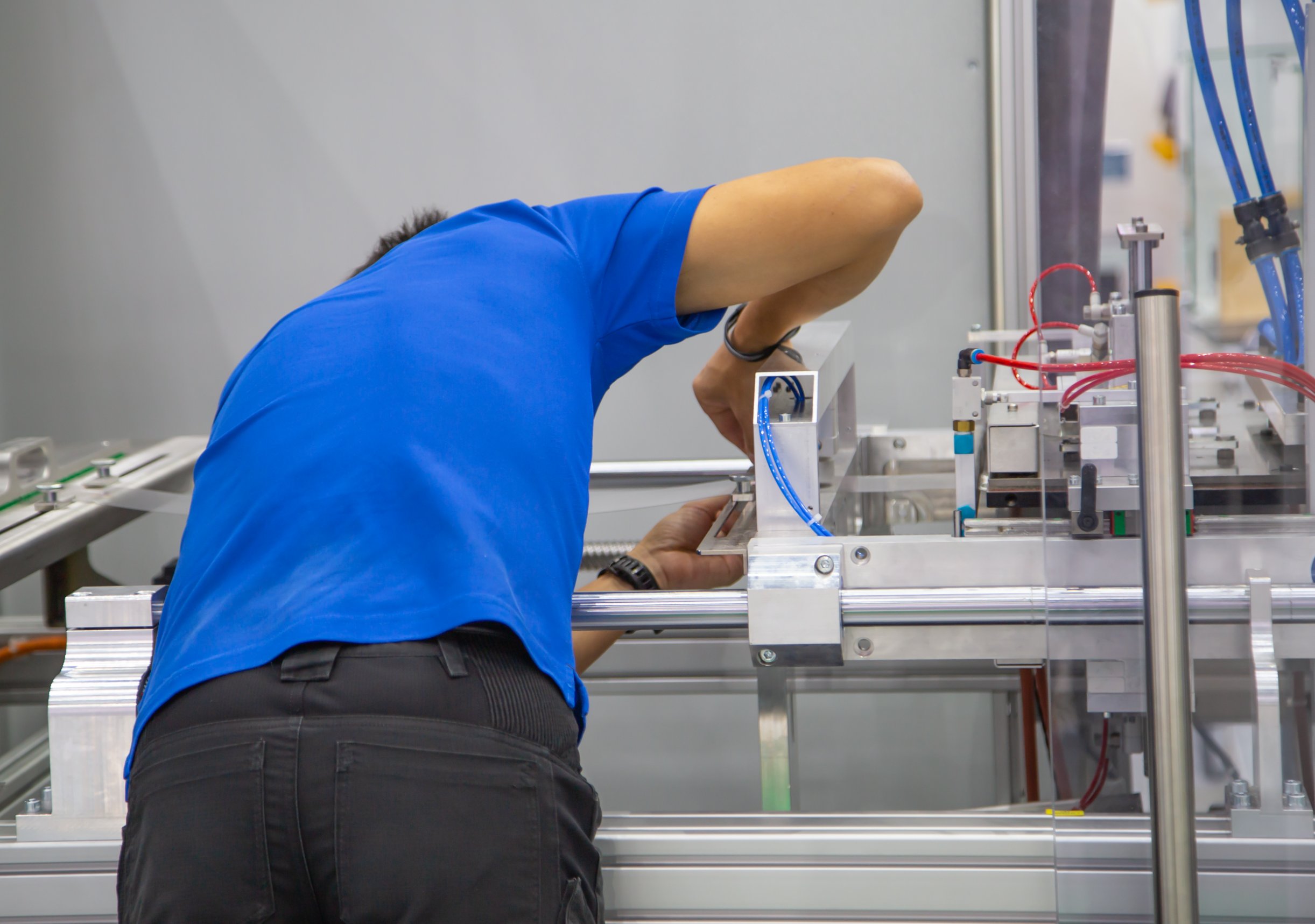

Maintaining your packaging equipment is critical for ensuring that your production process runs smoothly. Here are some tips to help you keep your packaging machinery in good condition.

Schedule Preventative Maintenance

Preventative maintenance is key to keeping your packaging line running smoothly. By scheduling regular check-ups and servicing your equipment, you can catch potential problems before they cause downtime or production issues. Preventative maintenance should include, at a minimum:

- Machine inspection

- Monitoring and changing wear parts regularly

- Ensuring high-wear parts are kept in stock

- Lubricating the machine

Keeping your packaging line equipment clean and well-lubricated will help to prolong its life and prevent problems with jams or other production issues.

Keep an Equipment Maintenance Log

Keeping a detailed log of all the maintenance and repairs that have been performed on your packaging line equipment can help you keep track of when things were last serviced, and can also help identify any patterns in equipment failures.

Be Mindful of Your Packaging Line Speeds

Operating your packaging line at high speeds can put a lot of wear and tear on the equipment. If possible, try to run the line at lower speeds, or use packaging equipment that is designed for high-speed operation.

Require Autonomous Maintenance Tasks from Your Operators

Autonomous maintenance tasks are simple checks and maintenance tasks that your packaging line operators can perform on a daily basis. These tasks can help to identify potential problems early before they cause major production issues.

Some examples of autonomous maintenance tasks include:

- Checking packaging line equipment for loose parts or damage

- Lubricating equipment

- Cleaning equipment

- inspecting conveyors for damage or debris

Make Repairs Immediately

If you do find damage or problems with your packaging line equipment, make repairs immediately. Allowing packaging line equipment to operate with damaged or worn parts can cause further damage and can lead to production issues.

Plan for Upgrades and Replacements

Packaging line equipment will eventually need to be replaced. Planning for these upgrades and replacements can help to minimize downtime and production disruptions.

Packaging Equipment Designed for Your Business

These are just a few tips to help you keep your packaging line equipment in good condition. By following these tips, you can help to prolong the life of your packaging machinery and keep your production process running smoothly.

Choosing a high-quality manufacturer of packaging equipment is another crucial requirement for ensuring your equipment is in its best shape. Reputable manufacturers can provide guidance and support to keep their machines running with optimal efficiency. For more information on how we can customize our packaging equipment to meet your exact production line needs, call (781) 986-7500 or contact us online.