Automated Carton Erecting for Speed, Safety & Labor Savings

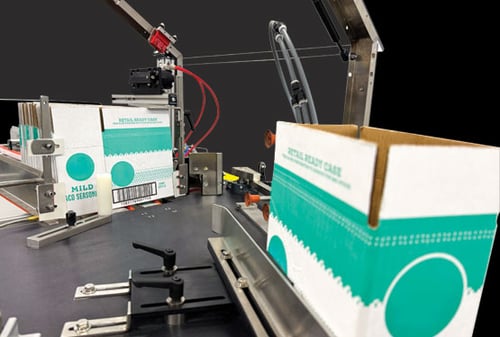

The Econocorp Auto Bottom Erector is a intermittent motion machine designed to automatically erect auto-lock (auto-bottom) style cartons, enhancing efficiency and safety at the start of your packaging line. This semi-automated solution reduces manual labor by forming flat corrugated or folding carton blanks into fully erected cartons—ready for operators to load and close manually.

With speeds of up to 30 cartons per minute, the Auto Bottom Erector provides a reliable, consistent way to streamline your packaging process, boost throughput, and lower labor demands.

Intermittent Motion Design for Smooth, Consistent Operation

Built for intermittent motion performance, the Auto Bottom Erector keeps your packaging line moving. Cartons are picked from a magazine via vacuum arm, opened using pneumatic components, and formed into their auto-lock shape in one fluid motion—ready for the next stage of your process.

With a compact footprint and sanitary design, it’s easy to integrate into a variety of production environments, from food and personal care to consumer goods and industrial packaging.

Improve Carton Assembly While Reducing Manual Labor

Carton erecting can be repetitive and physically demanding. The Auto Bottom Erector automates this step, consistently forming auto-bottom cartons that spring into shape and are ready to fill—without gluing or flap sealing.

Operators no longer need to fold cartons by hand, saving time and reducing strain. This improves both line efficiency and employee well-being, especially in environments with high daily volume.

Auto Bottom Erector Specifications

| Specifications | Details |

|---|---|

| Speed | Up to 30 cartons per minute (2,100/hour) |

| Carton Style | Auto-Bottom / Auto-Lock |

| Carton Size Range | Min: 4” L x 1” W Max: 12” L x 12” W |

| Power Requirements | 115V standard (220V optional), 50/60 Hz, Single Phase |

| Air Requirement | 60 PSI (4 bar), ~3.2 CFM (30 L/min) |

| Shipping Weight | Under 600 lbs (136 kg) |

| Motion Type | Intermittent Motion |

| Footprint | 82.72L x 43.47W x 55.09H |