Case packing is a critical, yet underappreciated component of product manufacturing and transport. Without a reliable cartoning system, your packages and products become vulnerable to damage and loss. Just as bad, your brand name loses credibility with customers.

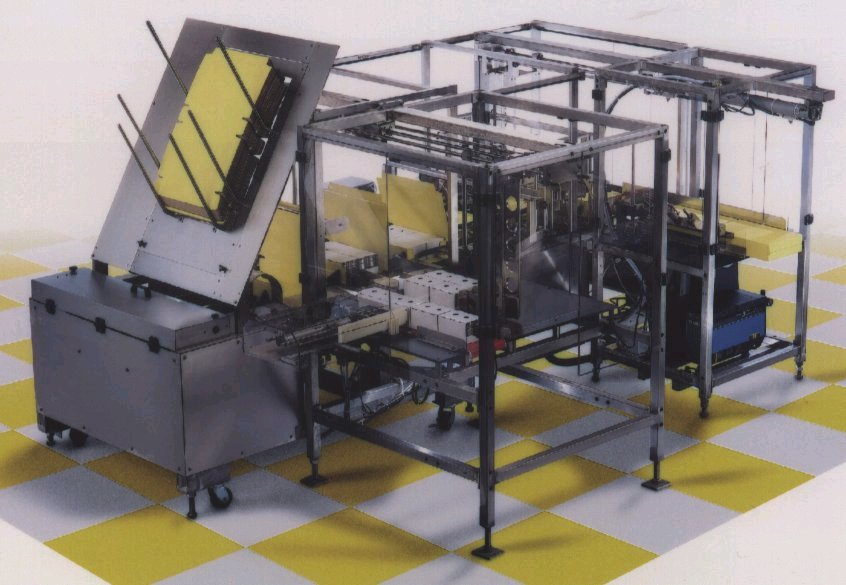

Econocorp’s Wrap Around Spartan Case Packer offers a compact solution for wrap-around carton, case, and tray packaging.

Sanitary Construction

The Wrap Around Spartan Case Packer is constructed of heavy duty, welded stainless steel. This sanitary construction is safe and effective when handling food products, medical products, and other sensitive items.

Simple and Fast Changeover

The Spartan Case Packer works by forming blank corrugated or paperboard materials into a “U” shape and transporting it to a product load station. Products can be automatically or manually loaded into the collating device. Once the products, such as frozen pizzas or yogurt containers, are situated, the loaded packages move through a series of closure/end flap gluing stations.

Gluing is done by a hot melt extruding system. For full wrap-around packing styles, the right angle transfer device accommodates side joint gluing as well. This entire process is simple and fast. The carton, case, or tray is finally discharged as a complete package ready for transport.

The case packing system created by the Wrap Around Spartan is ideal for 12-pack beverages, snacks, food tubs, and food trays. Expect output of up to 20 cartons per minute.

Accommodates Paperboard and Corrugated Materials

With the Spartan Case Packer, you don’t need to choose between one or the other. This machine accommodates paperboard and corrugated materials. This flexibility makes it easier to switch between products and packaging types without hassle.

To improve your own product packaging and maximize output while minimizing costs, call (781) 986-7500 to speak to a representative at Econocorp. One of our packaging sales representatives will help you find the information that you need to use the machine best suited for your diverse packaging needs.