In today’s competitive craft beverage market, the packaging line is more than a potential bottleneck to manage — it’s a critical part of your brand’s ability to scale efficiently, maintain quality, and keep margins in check. As supply chain leaders and engineers know, selecting the right beverage packaging equipment partner isn’t just about the machine — it’s about finding a vendor who understands your production environment and can support long-term growth and operational goals.

Here are four key considerations you should evaluate when selecting a beverage packaging machine partner for your craft beer or beverage line.

1. Proven Beverage Packaging Machine Knowledge and Industry Experience

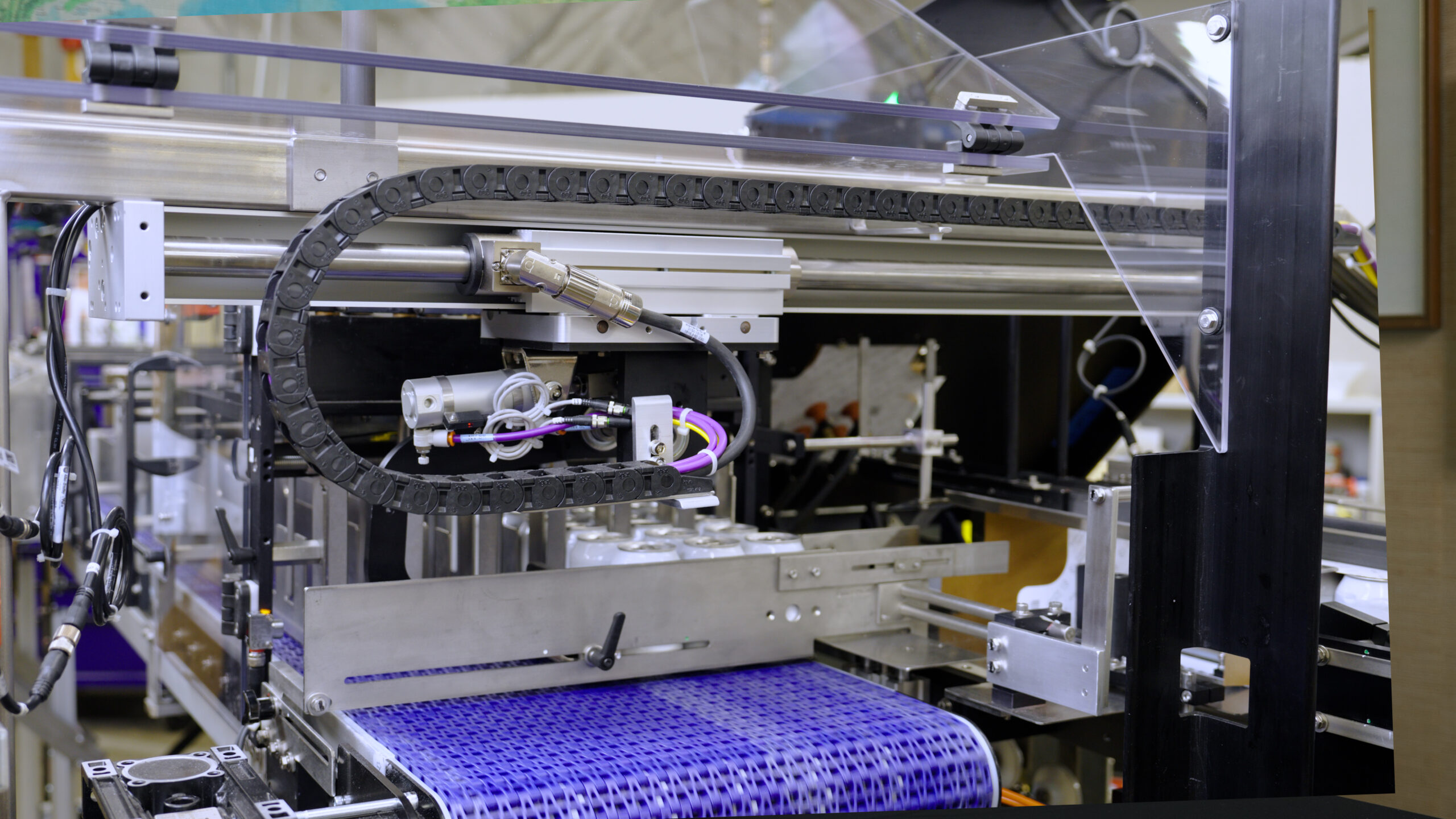

Integrating beverage packaging machines like cartoners or tray packers into a craft beverage line involves more than just plug-and-play equipment. From canning and sleeving to multipack configurations and end-of-line handling, the beverage packaging equipment manufacturer you choose should understand your production challenges and have the track record to back it up.

You’ll want to make sure that your beverage packaging machine provider has experience in beverage-specific applications and working in brewing or beverage production environments. Beverage packaging machines that are designed with flexibility and simplicity at the forefront will deliver reliable results with lower total cost of ownership due to lower repair costs, maximal uptime, and versatility – allowing your beverage cartoning line to be used in different configurations as your operation evolves.

Even though a beverage packing machine is an upfront capital investment for any beverage company, it will pay for itself over time. The machine will save your company money as it fills labor gaps on the packing line, increases throughput, and in situations where you select automated features, it can eliminate the need for human interaction completely, thus allowing you to use those resources in other critical areas of your business where their skills are better suited.

2. Flexible System Design for Your Changing Needs

Today’s beverage packaging lines need to be flexible and forward-looking. That means the ability to run a variety of carton, sleeve, and tray formats — from 4-pack and 6-pack wraparound cartons to custom variety packs — with minimal tooling changeover.

Regardless of your company’s size and scale, it will serve you well to have a cartoning system that is modular and flexible for your beverage packaging environment so that it can grow with you. Whether you’re hand-loading during startup or transitioning to high-speed infeed automation, equipment designed with flexibility in mind scales with your operation. Custom lane configurations for variety pack creation, quick-change capabilities, and compatibility with upstream and downstream OEMs make flexible cartoning systems a must for evolving line layouts and business models.

3. Built to Last – With U.S.-Based Support

Durability and reliability are non-negotiable — especially when uptime and maintenance costs are under constant scrutiny. Your company will benefit from a flexible beverage cartoning system that is designed and built in the U.S., with a focus on simple, yet rugged construction, accessible components, and minimal maintenance requirements.

Rugged, yet economical cartoning systems prioritize mechanical simplicity, which translates into fewer points of failure and easier diagnostics for your in-house maintenance team. And if on-site support is needed, having a beverage packaging equipment manufacturer with a regional, US-based support team is beneficial for rapid response situations that will help get your line back up and running with great urgency. The final point to look for is the availability of a robust inventory of parts and responsive domestic support, which helps minimize unplanned downtime and supports leaner spare parts strategies.

4. Total Cost of Ownership That Keeps You Competitive

With capital expenditures under pressure and cost-per-case metrics more important than ever, beverage packaging equipment selection must be made with both short-term ROI and long-term TCO in mind. A partner with a reputation for designing and building high-quality, flexible, but economical equipment at a competitive price point without compromising on quality or performance, should be a non-negotiable in your sourcing process.

That rule applies whether you’re building out a new packaging line or upgrading aging equipment. Beverage packaging machines offer rapid ROI by increasing productivity, reducing labor costs, and maintaining consistent packaging quality. And with efficient changeover and quick maintenance, you get more uptime and throughput out of your existing footprint.

For beverage industry and craft brewing supply chain leaders and engineers seeking flexible, economical packaging solutions, partnering with a beverage packaging equipment provider that understands your world is essential.

Ready to Step up Your Craft Brew Packaging Game?