ECONOCORP Inc.

The Worldwide Leader in Cartoning, Tray Forming, and Case Packing for Low- and Moderate-Speed Production Lines

Since 1964

Economical Secondary Packaging Equipment

Since 1964, we’ve served everyone from emerging brands and contract packagers with economical secondary packaging equipment, all the way to large CPGs with advanced robotic solutions. Our simple-to-operate affordable cartoning systems, case packers, tray forming solutions, and palletizers empower those ready to automate.

We help you streamline operations and increase reliability and profitability–all while providing the flexibility to run multiple SKUs. All of our economical secondary packaging equipment offerings are backed by superior customer support and service to meet your seal of approval.

EconoCore Affordable Cartoning Systems

Reduce reliance on manual labor while increasing productivity with our Econocore family of affordable cartoning systems and carton sealers. These flexible solutions evolve with your business and handle both paperboard and corrugate, accommodating various package styles and SKUs. Whether you're starting out or expanding, our cost-effective solutions support your growth in every stage.

Our Econocore lineup includes:

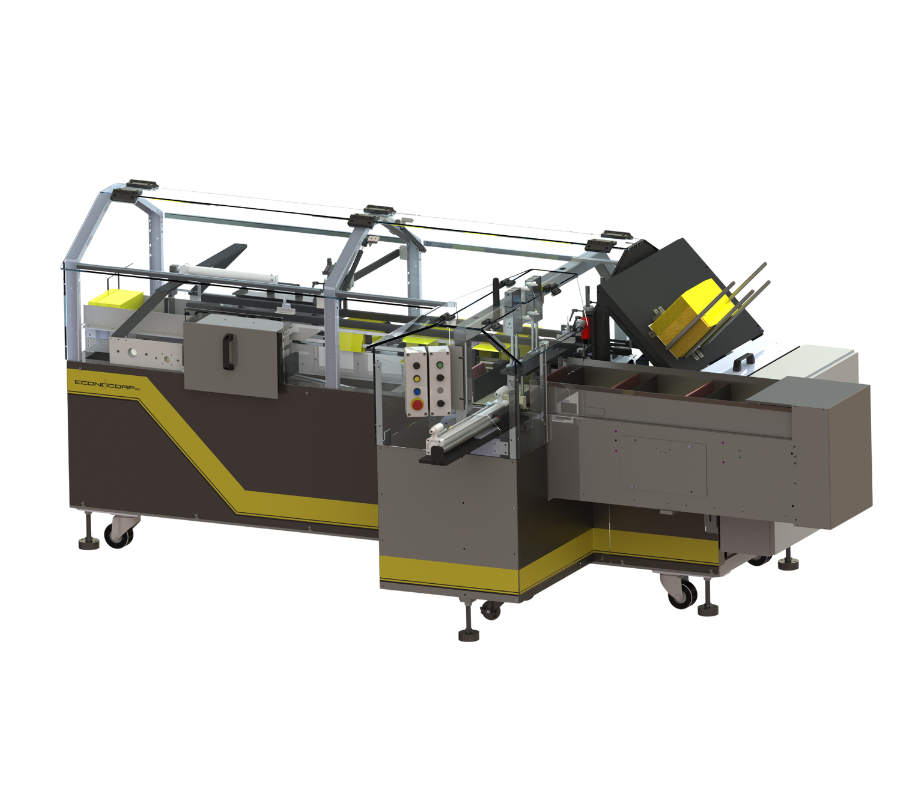

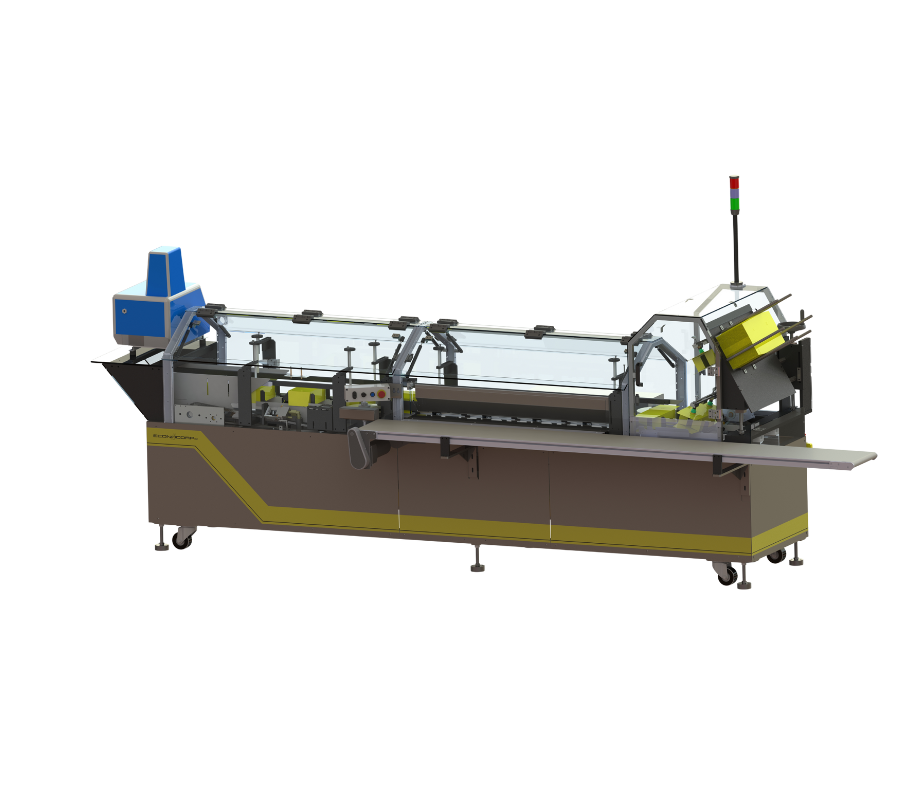

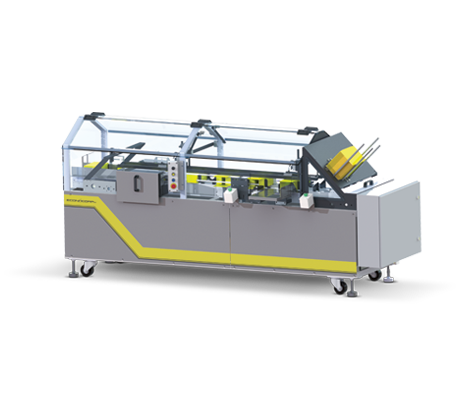

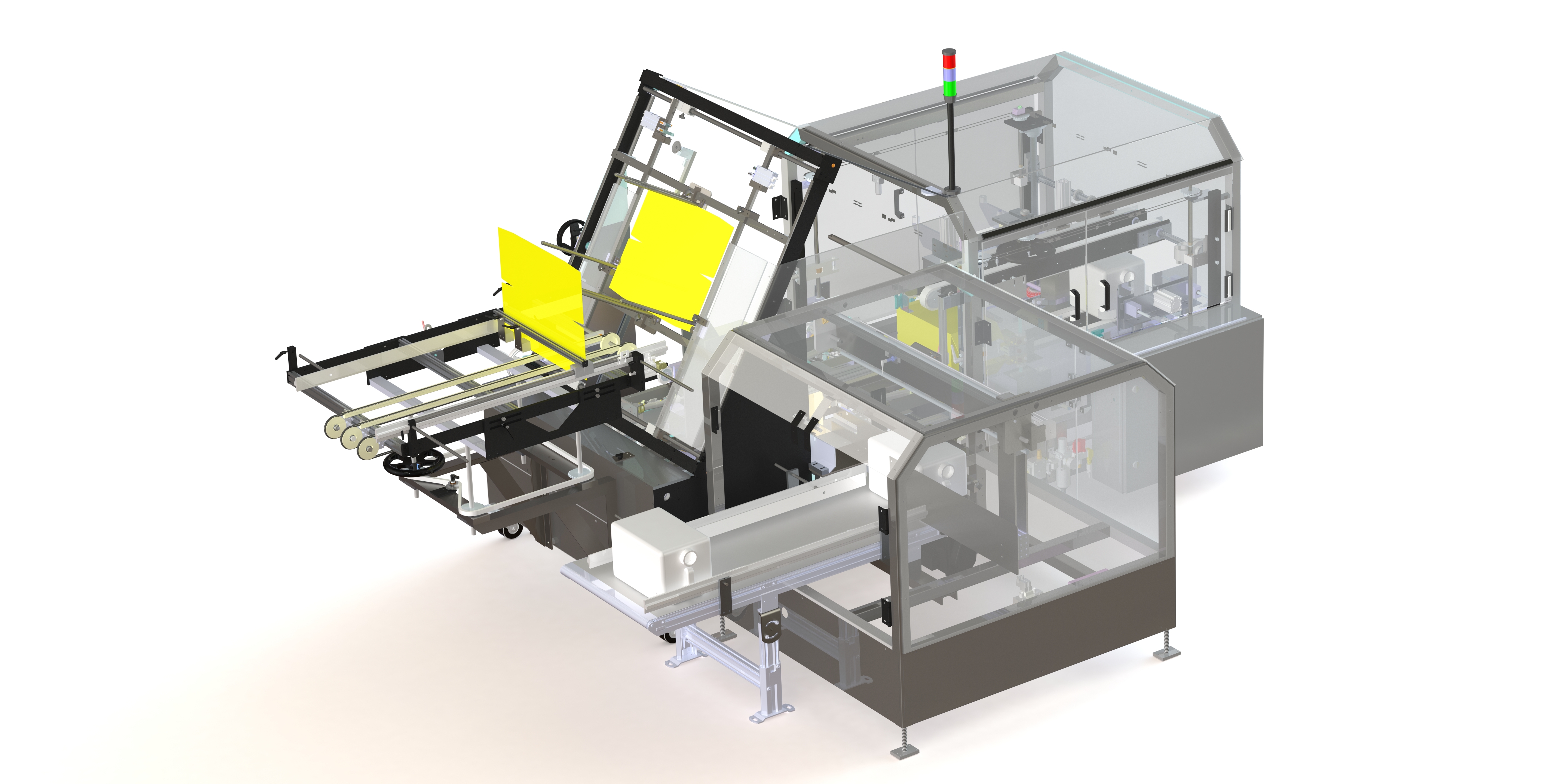

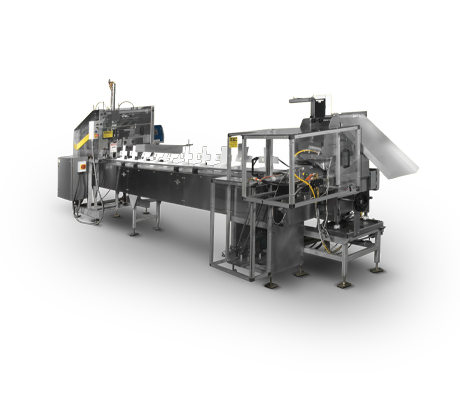

Spartan Versatile Cartoning Systems

The Spartan is a horizontal cartoning workhorse that fits in a small footprint. This economical, automatic intermittent motion horizontal cartoner is ideal for a variety of applications, including baking mixes, canned foods, confectionery, frozen foods, craft beverages, snacks, medical equipment, and more.

Adding to its flexibility, it accommodates glue sealing, tuck closure, gable top, or auto lock cartons, made of either paperboard or corrugate materials. The Spartan is available in three models:

-

Standard Spartan, suitable for food applications like bakery and baking mixes, snacks, confectionery, frozen foods, medical equipment, pharmaceuticals and more

- Spartan Plus, a full servo version of the Standard Spartan for increased speed and production volume.

-

Beverage Spartan, ideal for craft beer and spirits, iced tea, and other canned drinks

-

M-Pro, a compact version for small goods, including pharmaceuticals, nutraceuticals, cosmetics, personal care, cannabis, automotive, and industrial products

Choose Your Econocorp Solution

Cartoning Systems

Case Packers

Tray Formers

Palletizers

Resources and Support

Our Story

Education

Blog